Producing since 1962.

PICATORS | pce series

General Information

Our PCE mills are robust, high-performance machines, meticulously designed to meet the requirements of small and medium-sized meat processing industries, strictly complying with the safety standards of the latest EC Machinery Directive.

| MODEL | CAPACITY | AUGER CUTTING SPEED | AUGER FEEDER SPEED |

|---|---|---|---|

| PCE130.I | 260L | 300 min-1 | 29-57 min-1 |

| PCE130.II | 260L | 230-455 min-1 | 29-57 min-1 |

| PCE130.I.M | 320L | 300 min-1 | 29-57 min-1 |

Used in a wide variety of applications in all types of industrial processing units, fresh at positive temperature or in small frozen pieces down to -7°C.

They include certified safety devices and locks for the protective cover and service ladder. IP65 buttons and selector switches can be found on the control panel. It also provides extended security and device failure information.

The entire structure of the chipper is made entirely of solid stainless steel. All edges are rounded and all surfaces are very precisely polished and designed with a slope that allows the cleaning water to drain completely from all surfaces.

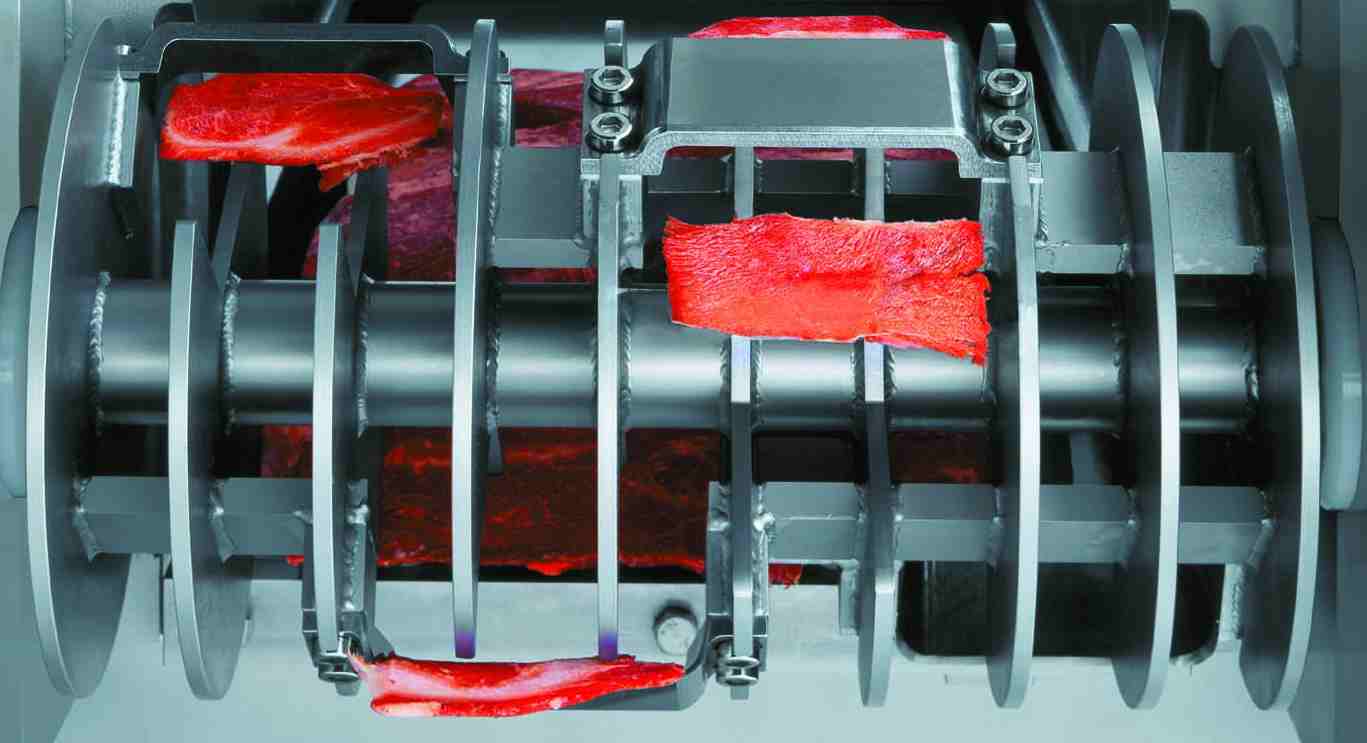

Specially designed to prevent wear, easy access and tool assembly, the 130 mm hole plate cutting system supports standard hole plates and cutting knife combinations.

Depending on the temperature, size and type of product, it is always possible to select one of the two auger speeds available. The standard machine includes two cutting knives, a pre-cut plate and three hole plates, 5, 13 and 20 mm respectively.

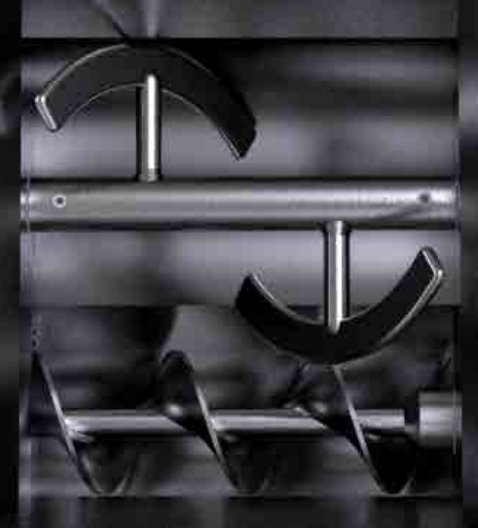

Our PCE130 II model has two grinding speeds, extending its range of applications. Depending on the temperature, size and type of product being processed, users can easily select one of the two speeds available for the screw feeder. The machine’s standard configuration includes two cutting knives, a pre-cutting plate and three perforated plates with diameters of 5mm, 13mm and 20mm, respectively. For specific food products, our mill can be supplied with a mixing system. A T-shaped paddle is mounted inside the hopper and rotates at a constant speed of 16 RPM.

STAINLESS STEEL SUPPORT TABLE Stainless steel work table, providing a robust support for removable components. This feature guarantees efficient handling and organization, optimizing workflow and convenience in your operations.

2-SPEED WORKING VERMIN Upgraded from the PCE I (1 working speed) to the PCE II, which comes equipped with an additional grinding speed.

ELECTRIC COLUMN LIFTER (MODEL ELIC200) Upgrade your grinding machine with our optional vertical electric loader, replacing the standard hydraulic version. This innovative feature offers effortless loading, precise control and space optimization, increasing productivity and safety.

PRE-MIXING ARM Our grinders can pre-mix meat products thanks to a T-shaped mixing paddle placed inside the machine’s working area. This feature can be controlled via the machine’s control panel.

Analysis and Corrections:

- Correction made: The translation was carried out to adapt the technical content to the context and language of Portuguese in Portugal, including the replacement of specific terms (“grinder” for “mill”, “feeding worm” for “screw feeder”, “cutting knives” for “cutting knives”, “hole plates” for “perforated plates”, etc.).

- Correction made: “Our PCE130 II model features two grinding speeds” has been translated into a structure that better reflects the way product features are described in Portuguese.

- Correction made: The technical description and functionalities have been carefully adapted to maintain precision and clarity, respecting the standard technical terms used in Portugal.

Contact us now or request a quote.

PROPOSAL

+351 229 670 059

Rua Elias Garcia, 1957, Ermesinde, 4445-413, Portugal

[email protected]