MIXER M SERIES

General Information

Introducing the M SERIES MIXER, the pinnacle of efficiency, reliability and innovation in food processing technology. Precision-engineered and designed to meet the diverse needs of modern food production, our mixer stands out as a paradigm of excellence in the sector.

VACCUM/Z MIXING ARMS/ 1300L

| CAPACITY | VACUUM | SPEED VARIATION | PROGRAMMABLE CONTROLLER | CO2 REFRIGERATION | ARMS |

|---|---|---|---|---|---|

| 150L | x | x | Z, S or T | ||

| 300L | x | x | x | x | Z, S or T |

| 600L | x | x | x | x | Z, S or T |

| 1000L | x | x | x | x | Z, S or T |

| 1300L | x | x | x | x | Z, S or T |

PROGRAMMABLE CONTROLLER

- Touch screen with IP65 protection

- Automatic cycle control, programmable settings based on time, pause, vacuum, air and CO2 refrigeration;

- Operating safety alarms (tank, lid and elevator);

- Service diagnostics and maintenance data information.

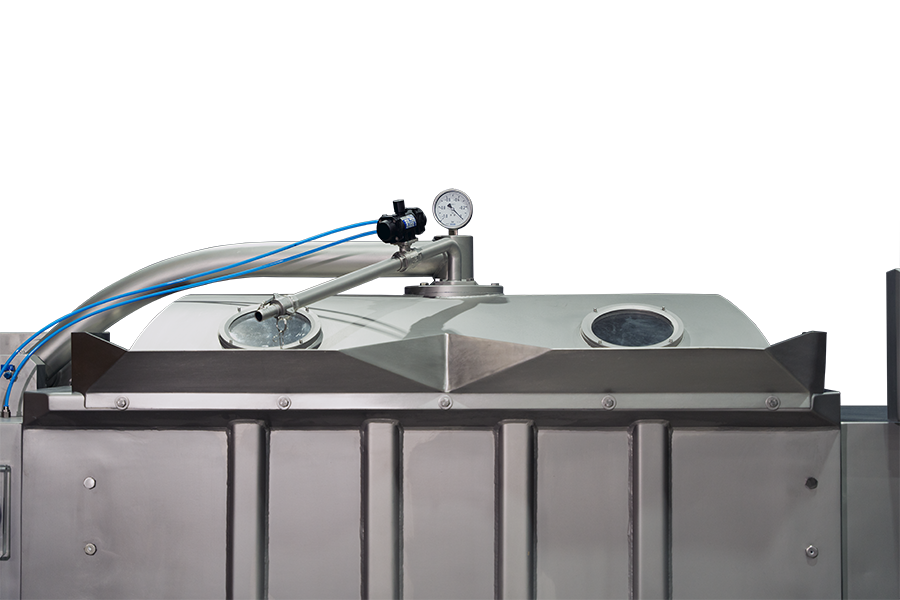

VACUUM SYSTEM

- Vacuum level can be set by a manual regulator and observed on the vacuum gauge.

- Includes a vacuum pump and filter.

- Vacuum pump capacity from 21m3/h to 100m3/h.

- Final pressure of the vacuum pump is 0.5 mbar.

SPEED VARIATION

- Speed frequency inverter to control the main electric motor.

- Mixing speed of 15 to 45 revolutions per minute.

CO2/N2 REFRIGERATION

- Temperature controller.

- Stainless steel tank lid includes a pneumatic valve for exhaust control, air ventilation windows and an observation window.

- Temperature reading via a PT 100 sensor.

System

We offer three types of arms, double and parallel (type ZZ, SS or TT) for the correct and efficient processing of various food products. Loading and unloading is done by an elevator with a rotating arm for 200L trolleys.

Suitable for mixing pre-cut meat and fat with salt, nitrite salt, spices or additives such as water or ice for the production of hamburgers, minced meat, sausages, nuggets, kebabs, vegetables, cheese products and much more.

Contact us now or request a quote.

PROPOSAL

+351 229 670 059

Rua Elias Garcia, 1957, Ermesinde, 4445-413, Portugal

[email protected]